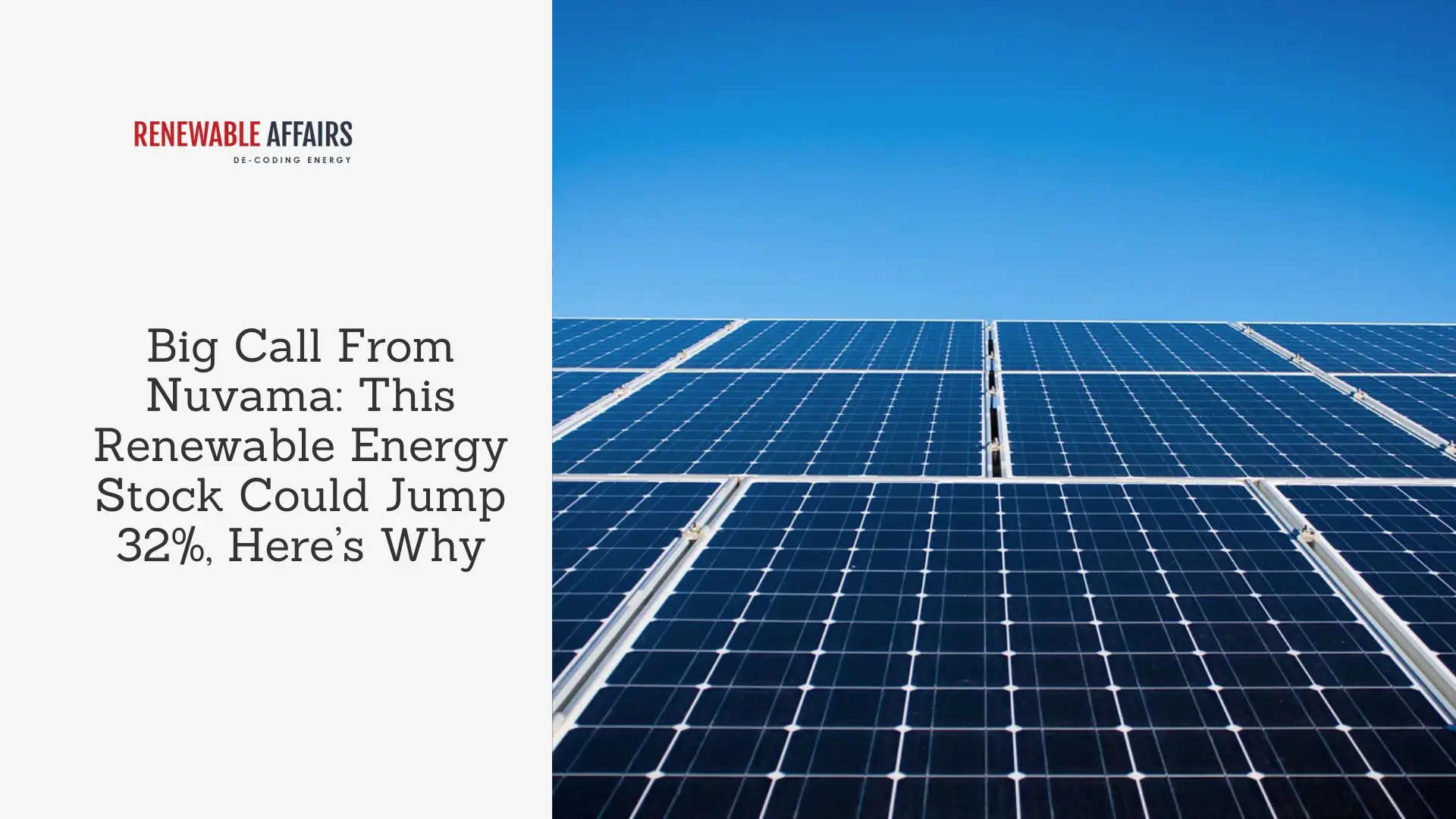

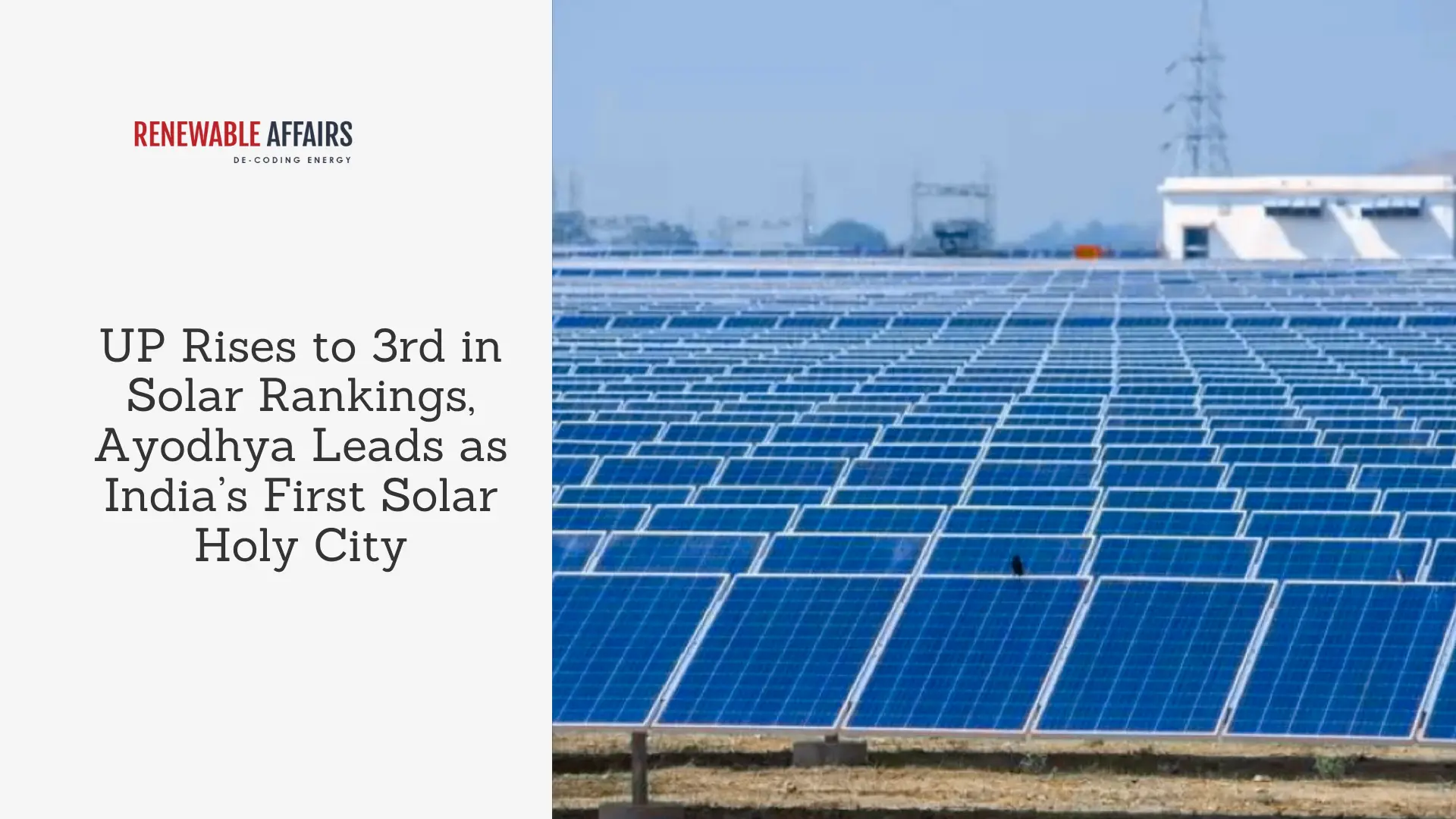

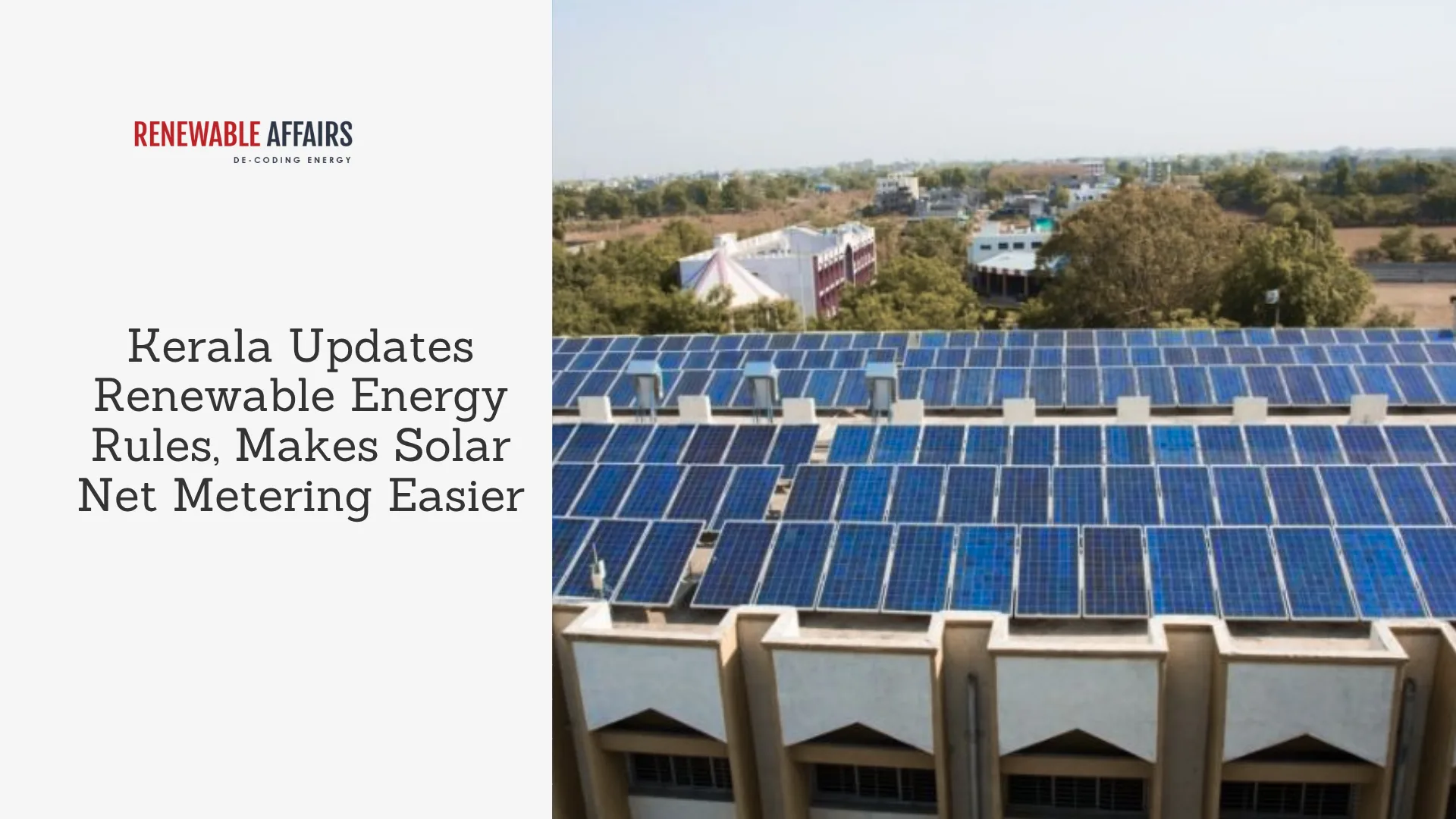

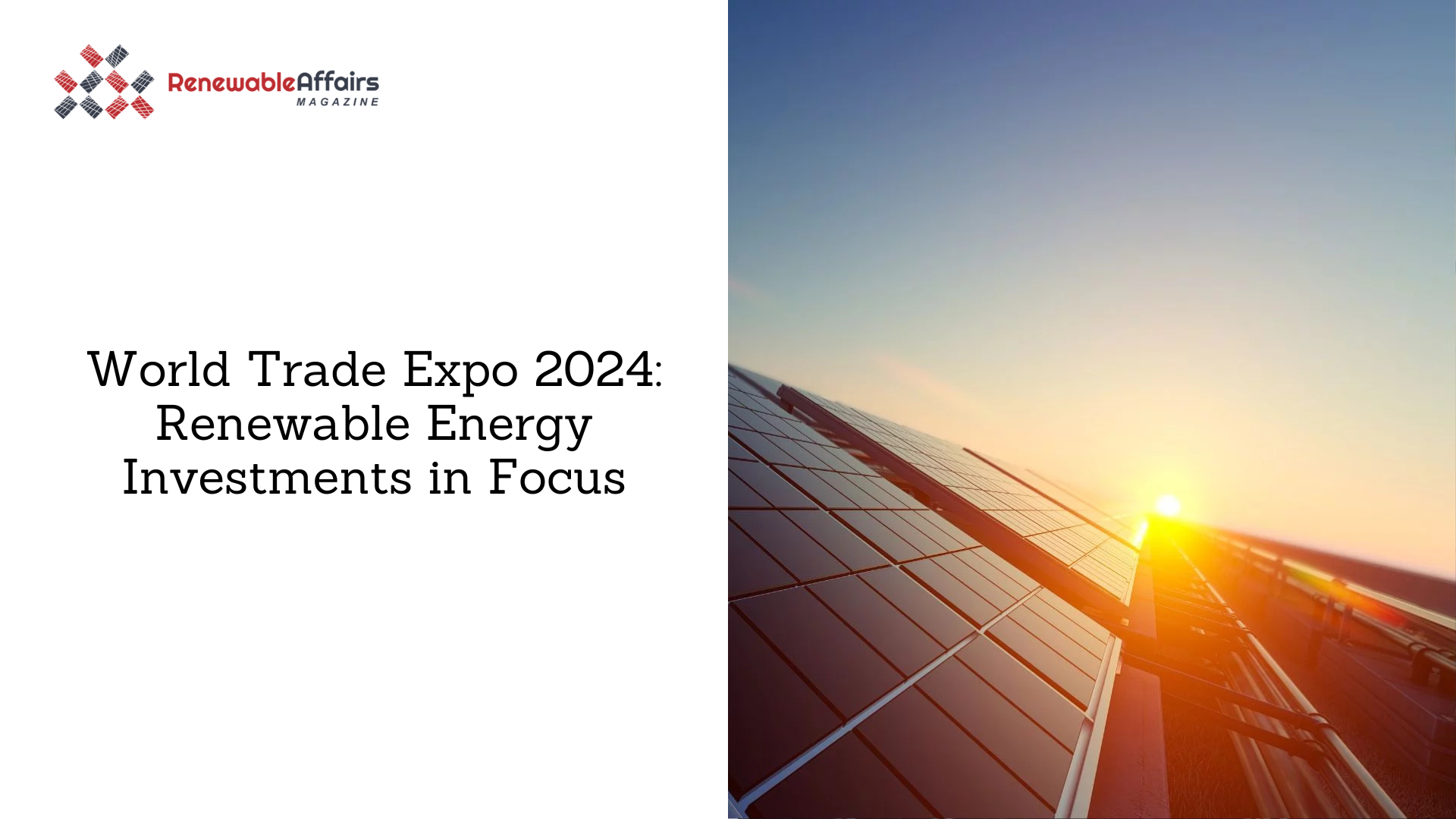

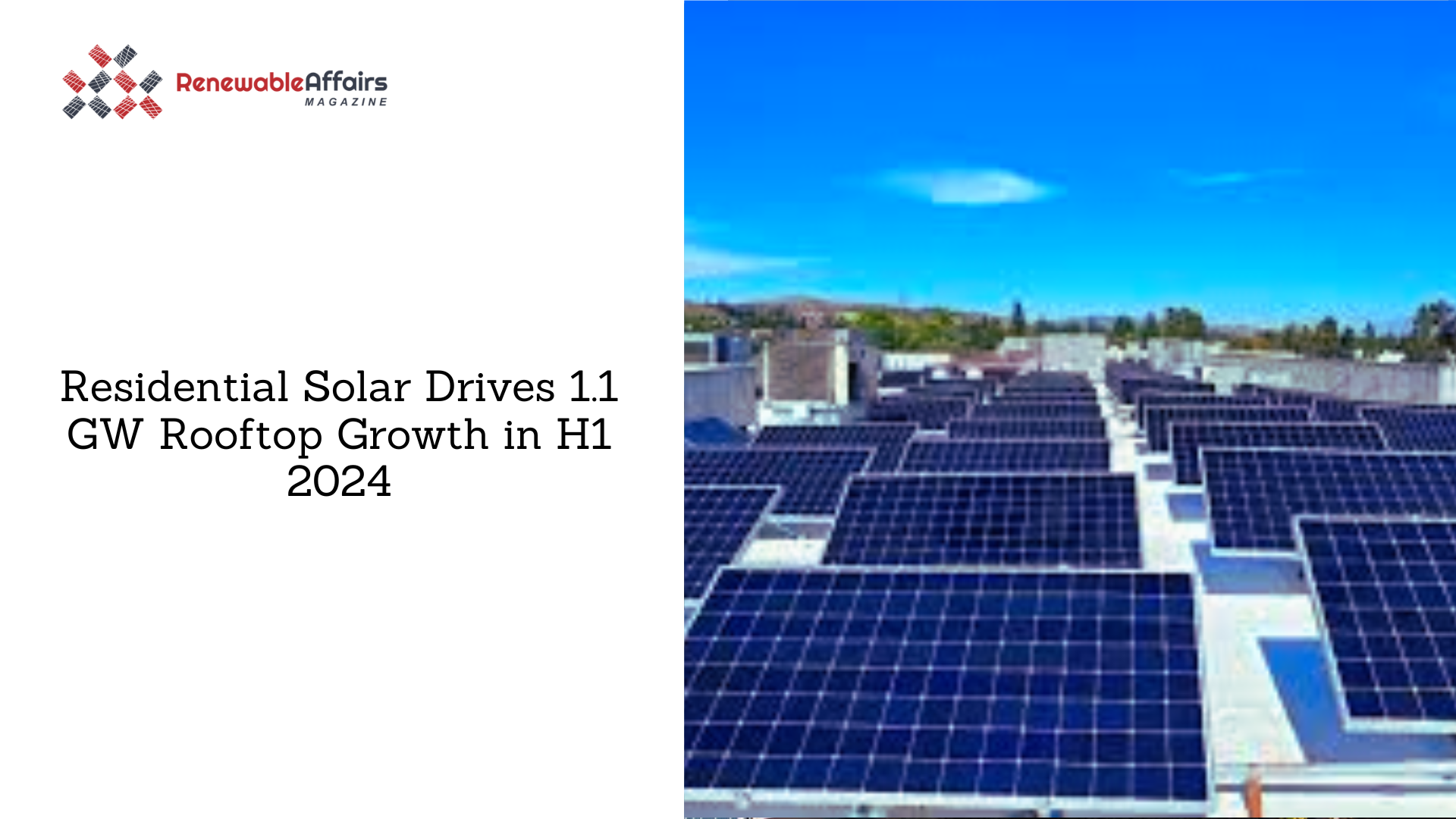

In recent times, many individuals and businesses across diverse sectors have installed solar panels. It is high time for everyone to realize the importance & potency of solar energy instead of depleting non-renewable sources of energy. If dependency on conventional energy sources continues, each person will be responsible for adversely impacting the environment.

There is no denying that solar panels are more commonly seen in many residential, commercial, and industrial settings nowadays. The common public’s awareness about using sustainable and renewable energy solutions has increased significantly. You must opt for the installation of solar panels sooner rather than later if you truly care for the environment. To run the solar panel, the components must be working and aligned properly. In this blog, we will look into some of the main components of solar panels

Crucial Components of a Solar Panel System

Different solar panel system components play a crucial role in their way, facilitating electricity generation. Here are the main components.

Solar Cells

The solar cell is the engine of a solar panel system, excelling in converting the sun’s light into electricity. These cells are usually made using silicon, a semiconductor element that can harness the sun’s energy via the photovoltaic effect. Upon hitting the silicon-made cell, sunlight triggers the movement of electrons, increasing their flow and generating an electric current.

- Mono-crystalline Silicon Cells: Experts manufacture these cells using a pure-quality, single-piece silicon crystal. Solar panel systems made of mono-crystalline silicon cells can efficiently convert sunlight into electricity.

- Polycrystalline Silicon Cells: The use of countless silicon crystals happens during the production of polycrystalline silicon cells. In terms of efficiency, they are not as powerful as mono-crystalline silicon cells. However, these are more cost-effective.

The total number of silicon cells a panel can fit usually depends on the expected output voltage and wattage.

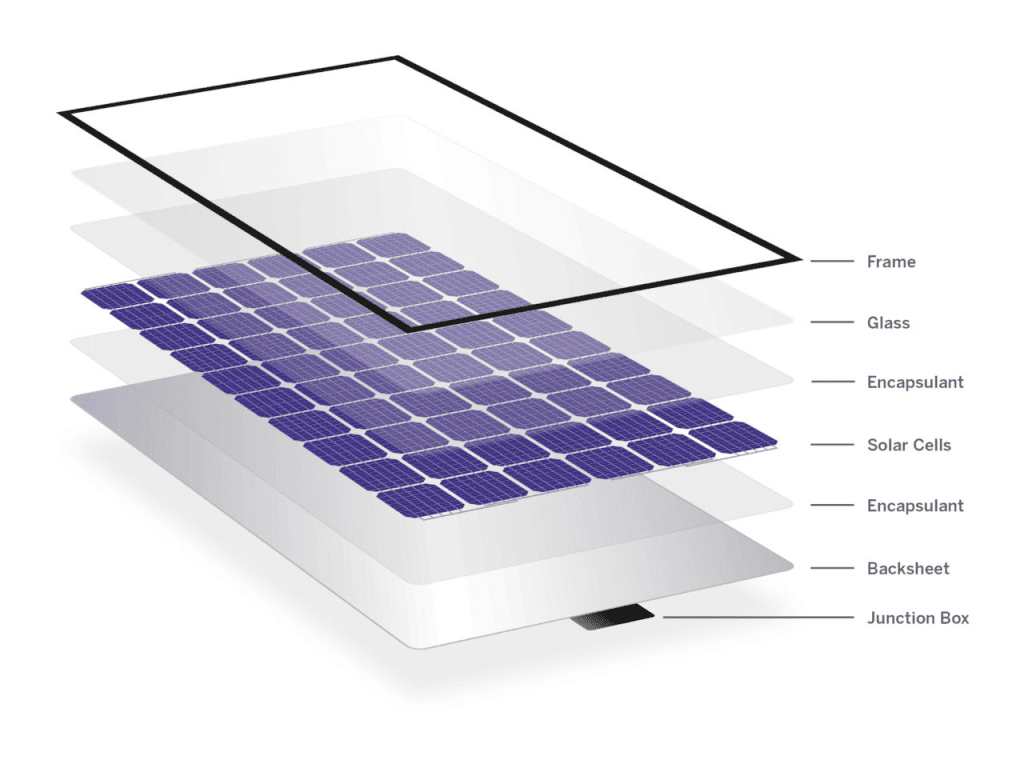

Back Sheet and Solar Glass

The delicate nature of solar cells compels experts to use appropriate elements to ensure top-level protection. Safety components such as a back sheet and solar glass are essential.

- Back Sheet: The rear end of a solar panel system consists of a back sheet, which acts as a shield. This component is generally made using weatherproof polymers. It ensures insulation, safeguarding the cells from dust, moisture, and current shock. It also helps in improving the mechanical integrity and durability of the solar system panel.

- Solar Glass: The top layer of a solar panel typically involves high-transparency, safety glass. This sturdy material permits maximum daylight infiltration while shielding the cells from hail, downpours, snow, and flying trash. Moreover, it is treated with a specific coating to reduce light reflection and capture optimal energy.

Frame and Encapsulants

A premium-quality encapsulant material excels in securely and seamlessly holding the solar glass, back sheet, and solar cells together. These encapsulants are usually Ethylene Vinyl Acetate layers, acting as a robust adhesive. They ensure that each part of a solar panel system is in its place during operation and endure extreme weather conditions.

Encapsulants: The extensively used encapsulant guarantees remarkable adhesion properties. They play a crucial role in protecting cells from environmental stresses. However, you must keep in mind that EVA can deteriorate with time because of continuous exposure to higher temperatures.

Frame: Experts encase the whole solar panel assembly within a well-built frame made of anodised aluminium. The frame functions in different ways, including structural support, heat dissipation, and mounting. As a result, a solar panel system becomes more rigid and capable of enduring a load of wind, accumulated snow, and various other physical stress factors.

Each frame consists of mounting-specific mechanisms or pre-drilled holes to ensure the secure installation of solar panels on rooftops. Solar cells do not become excessively hot, as aluminium-made frames help dissipate heat. Optimal solar cell temperature maintenance is a must for generating electricity efficiently.

What does the Electrical Network of a Solar Panel Comprise?

The main objective of solar panel systems is to power different appliances, gadgets, and machines in homes and offices. After solar cells convert the sun’s light into electricity, a complicated and detailed network of electrical components starts working.

- Junction Box: This is located at the rear of a solar panel system. It has a host of safety features and electrical connections, so making it weatherproof is of the utmost importance.

- Busbars: These copper-made metal strips run right across the rear and front parts of interconnected cells of a panel.

- Cables: Heavy-duty wires are adequately insulated for safety purposes. These cables effectively carry the direct current electricity to the inverter from the junction box.

Some solar panels comprise bypass diodes placed inside the junction box. These diodes restrain current from flowing again into shade cells, guaranteeing the optimal performance of a solar panel system. Each solar panel component is crucial in facilitating the efficient generation of electricity from sunlight. It is only when all major parts work together, that attaining the goal of electricity conversion is possible.

How do Experts Manufacture Solar Panel Systems?

The manufacturing procedure of solar panels begins with solar cell development. The experts follow specific steps, including doping, layering, and etching. After the production of solar cells, experts solder them together to prepare a panel. It is accountable for the drop in voltage and ensures seamless electrical connections.

Experts install a front glass layer, a back sheet and a frame to create a sturdy structure that helps convert energy efficiently. The junction box facilitates hassle-free connection and disconnection from the inverter and regulates the performance and safety of the solar panel system. Quality testing is necessary to ensure panels function properly and deliver excellent performances.

Working Process of a Solar Panel System

Solar panels consist of light-sensitive solar cells. Usually, solar cells are made of silicon that harnesses the sun’s energy via the photovoltaic effect. This immediately generates a direct current electricity flow inside each cell. The connected cells are instrumental in channeling the current through the internal wiring. An inverter helps convert direct current into alternating current.

Installing a branded solar panel system is necessary to reap many advantages. You can trust solar energy if you want to power different devices in your residential or commercial space. It is advisable to invest in energy-efficient and durable solar systems. The one you install must be capable of capturing sunlight in an effective manner so that it takes less time for the electricity conversion process.

Conclusion

You can make an informed decision now that you have become aware of the key components of a solar panel system. It is judicious to get a solar panel system from a leading and trusted manufacturer that will also provide maintenance services. If it features high-quality components, your solar panel system will last for many years and help you save substantial money in the long term.

0 Comments