Ministry of Steel, Director Neha Verma addressed at an event saying that India’s steel industry is one of the largest in the world and plays a big role in the country’s economy.

However, it also has a huge impact on the environment because making steel releases a lot of carbon dioxide (CO2). The steel sector is responsible for about 12% of India’s total emissions, which makes controlling these emissions a big challenge.

India currently emits 2.54 tons of CO2 for every ton of crude steel produced, which is higher than the global average of 1.91 tons. This high level of emissions is mostly because the steel industry relied on coal for energy.

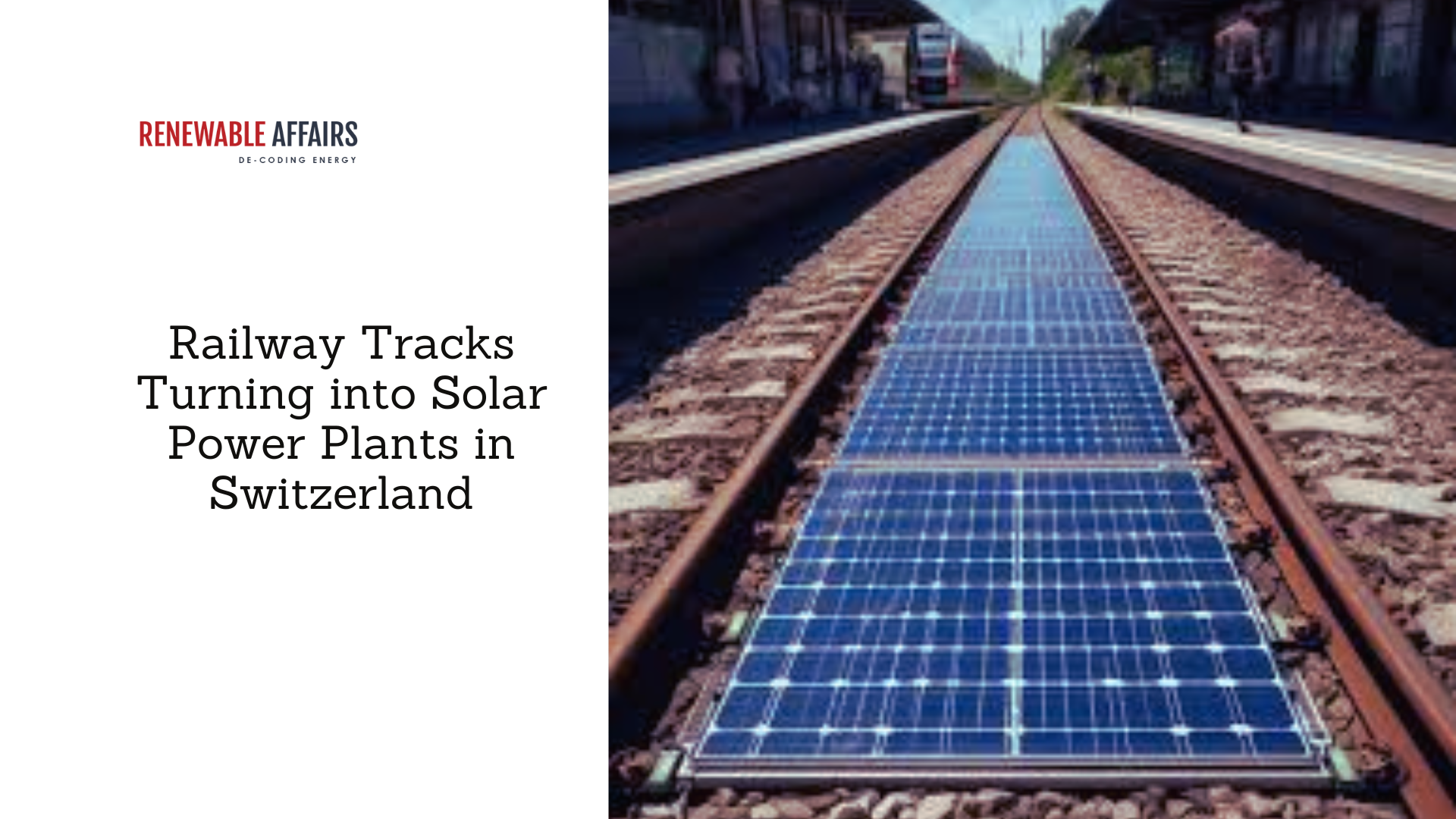

Verma pointed out that energy efficiency and the use of renewable energy are key short-term strategies to lower emissions. She said, “Energy efficiency alone can help us reduce emissions by more than 12%.”

India’s steel industry uses more energy per ton of steel than the global average. If the industry increases the use of renewable energy like solar and wind by 50%, it can reduce emissions by another 10-12%.

However, the cost of adopting these new technologies is a challenge for many companies in the steel sector.

In addition to energy efficiency, recycling steel, or using “scrap steel,” is another way to cut emissions. Using more scrap steel can lower the emissions to 0.5 tons of CO2 per ton of steel.

Currently, India uses approximately 21% of scrap in its steel production, while countries like the United States use it at a very big level which is 65%.

In the long term, India is experimenting with the use of green hydrogen as an alternative to coal in steel production. Green hydrogen does not produce carbon emissions, and it has the potential to fully replace carbon in the steelmaking process.

However, the cost of green hydrogen is still very high, which makes it hard for many companies to adopt it right now.

Verma also talked about carbon capture technology, which can absorb the carbon dioxide that steel plants release before it reaches the atmosphere. This technology can cut emissions by 50%, but because of its high cost, it’s difficult to implement on a large scale.

The government is also playing a supporting role in the transition to greener steel production. The Ministry of Steel is working on policies that will define what “green steel” is and encourage its use in public projects. If just 20% of the steel used in public infrastructure is green, the overall environmental benefits would be huge.

0 Comments