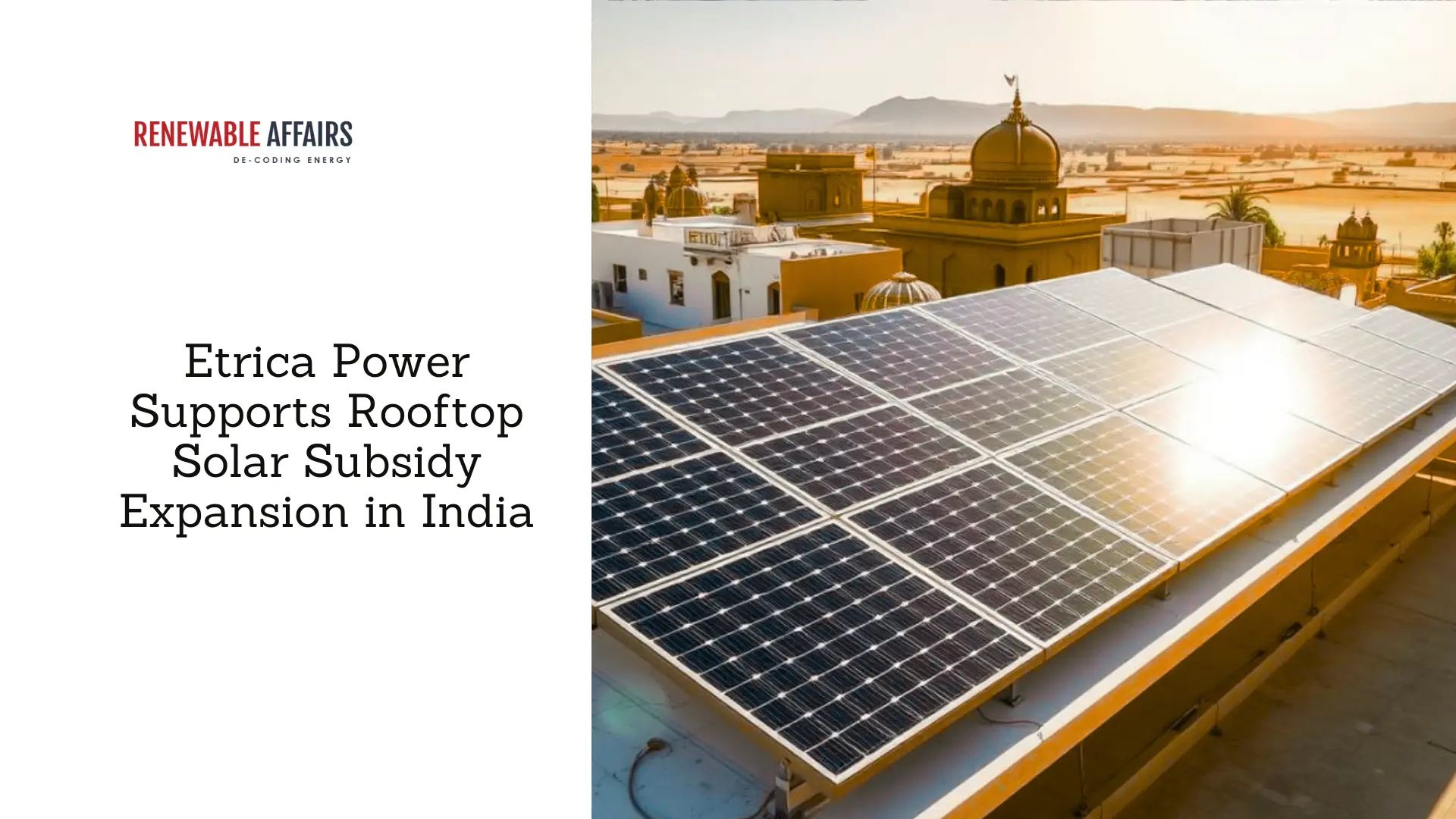

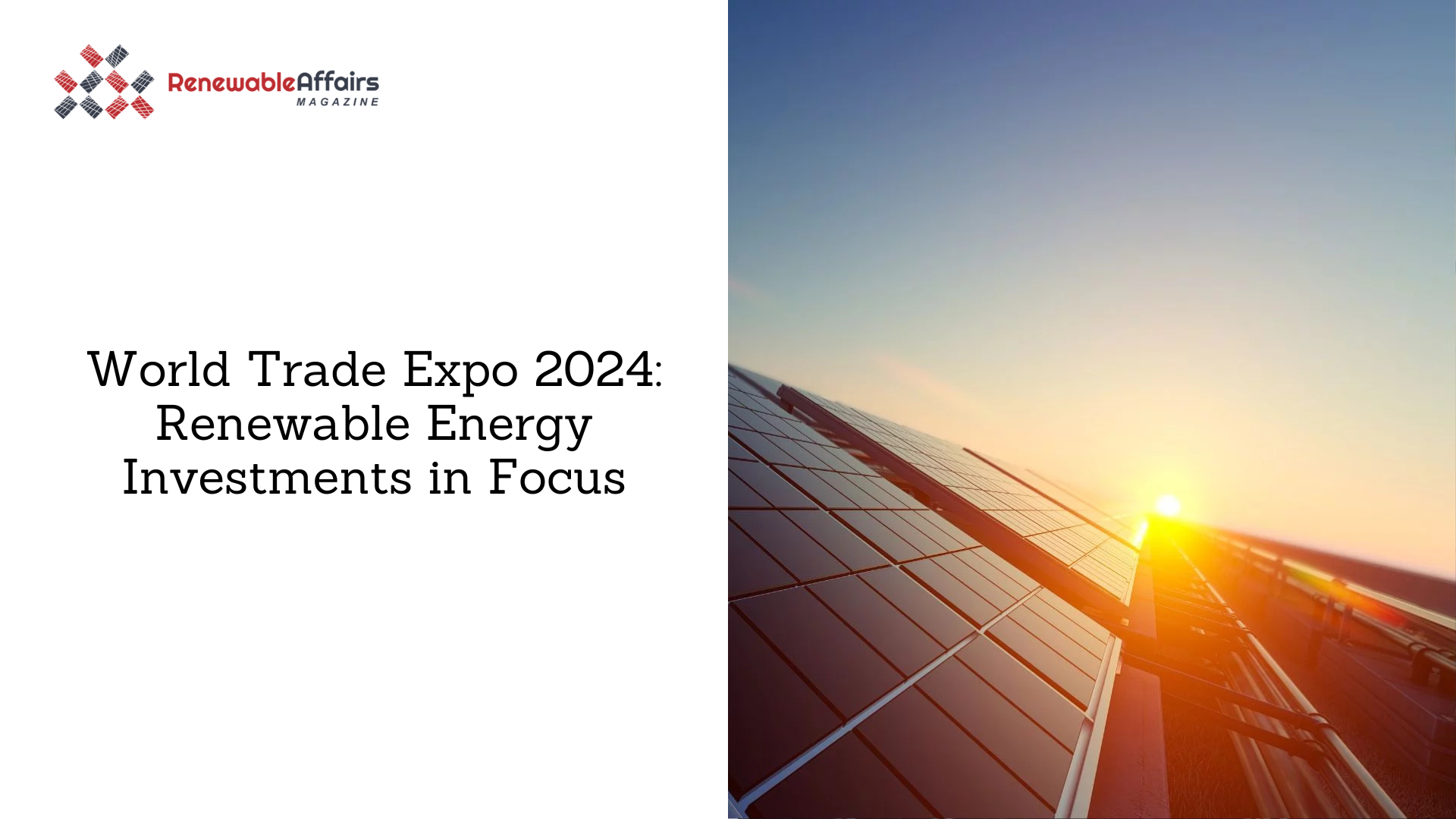

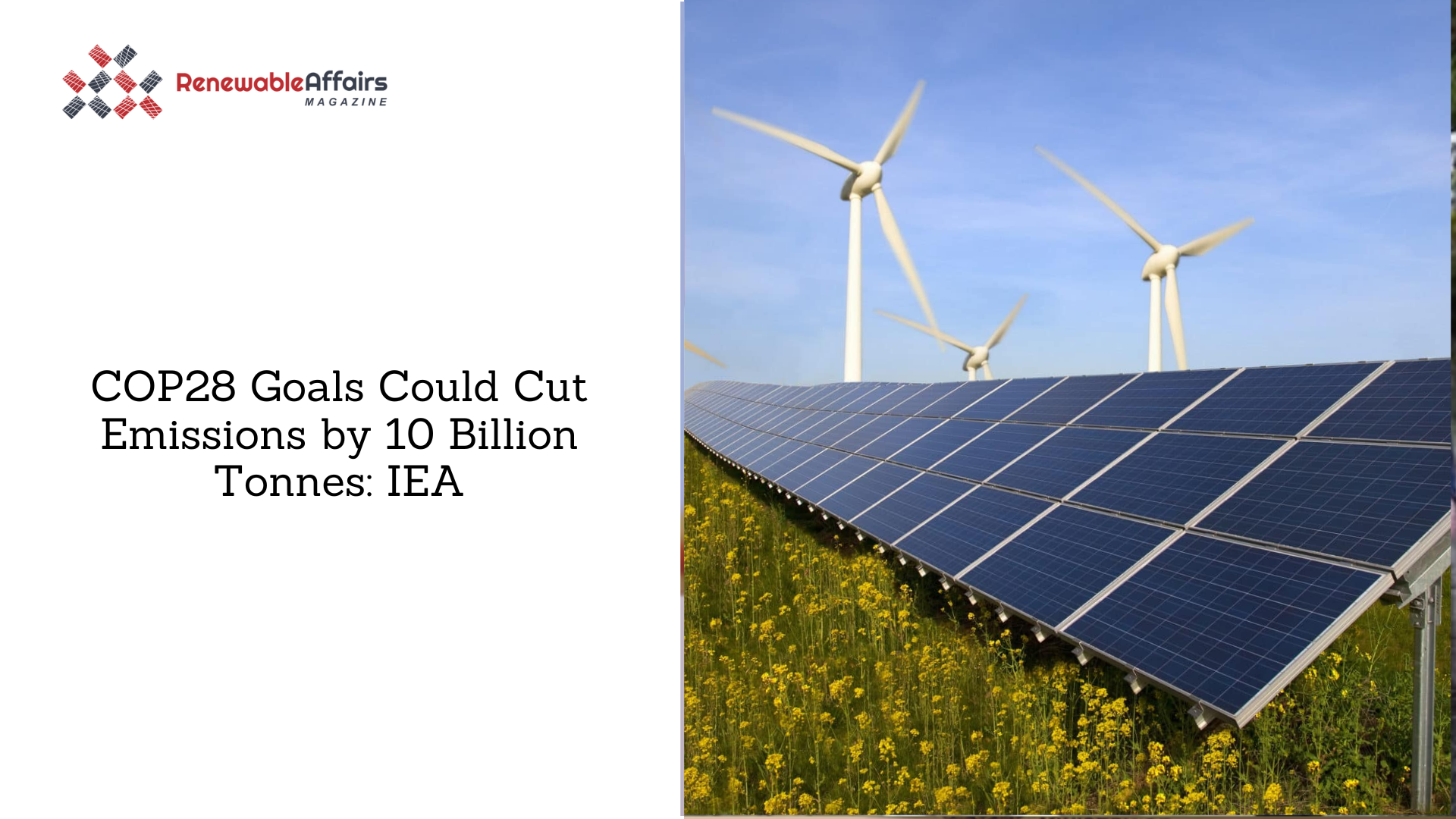

As the world embraces sustainable energy solutions, solar panels have started emerging as a popular choice for homeowners. Installing them helps reduce their carbon footprint and energy bills simultaneously.

However, the solar panel market is not one-size-fits-all. So, to help you make an educated choice, we have made a guide for you covering the various types of solar panels available, each with its unique characteristics and advantages.

What is a Solar Panel?

Solar panels, often referred to as PV panels, are ingenious devices designed to transform sunlight (which consists of tiny energy particles known as ‘photons’) into electrical energy.

This electricity can be harnessed to power an array of applications, including but not limited to off-grid power sources for cabins, telecommunications infrastructure, and, notably, for generating electricity in both residential and commercial solar power systems.

Read More: Top Solar Panel Manufacturers in India

Types of Solar Panels in India

Monocrystalline Solar Panels

Solar cells are created from Silicon, a semiconductor material. In addition to being more effective at turning light into energy, this element is also widely available across the world.

In monocrystalline solar panels, silicon wafers are put together into rows and columns. They are then molded into a rectangle and covered with a glass sheet.

Solar cells in monocrystalline panels are created from a single silicon crystal. The name of the crystal is monocrystalline ingot. However, these solar modules cost more since the manufacture of these crystals is difficult and produces a lot of silicon waste.

Features:

- Monocrystalline panels are more costly than other panels as it costs more to make pure silicon crystals.

- The majority of monocrystalline panels come in greater power wattages, with power outputs up to 600 Wp.

- These panels have a much better efficiency than other varieties. Since technology has advanced, mono panels’ efficiency may currently exceed 20%.

- These solar panels contain cells with a black tint.

Monocrystalline panels are also available in half-cut cell technology. In this form, the square-shaped solar cells are split in half, resulting in a module with twice as many cells as before. Cells in the top section belong to one series, whereas cells in the bottom section belong to another.

As a result, even if the top part is covered, the bottom still produces energy. Cell panels that have been cut in half produce more electricity than their equivalents.

Polycrystalline Solar Panels

Polycrystalline solar cells are made from silicon crystal fragments. Due to this, polycrystalline panels are often referred to as multi-crystalline modules.

The silicon residue left behind after producing pure silicon crystals is mixed and melted into a mold. The mold is then cut into wafers to make solar cells.

Features:

- Poly modules are less expensive than mono panels because of the significantly easier production process.

- The efficiency of these modules is between 15 and 17 percent, which is lower than that of other kinds of panels.

- Poly panels often have lower power outputs since they are manufactured at lower wattages.

- Additionally, the color of poly panels is bluer.

(PERC) Solar Panels

Mono PERC (Passivated Emitter and Rear Cell) is an improved variant of monocrystalline modules.

In this process, the sunlight it gets is not completely absorbed by conventional modules. Most of it is reflected in the frame. Manufacturers of Mono PERC modules put a coating on the back of the solar cells to address this issue.

Features:

● The light that is reflected by the ground is absorbed by mono PERC modules.

● The panel outperforms every commercially available module on the market in terms of efficiency and power production.● These panels are more expensive than other available panel kinds.

Thin-film Solar Panels

Compared to the other modules, the thin film solar panels are less in weight and smaller. Thin film panels do not depend upon silicon for their production.

Three particular photovoltaic materials—cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon (a-Si)—are used to make the majority of thin film solar panels. Manufacturers sandwich the material between two transparent conductive layers of glass or plastic to create the panels.

Features:

● These panels are easy to install because of their small size and enhanced maneuverability.

● The panels are less expensive than other varieties since they are simpler to produce.

● Compared to all other varieties of solar panels, these panels have the lowest efficiency and power production levels.

● These solar panels are often used for utility-scale projects because of their short lifespan, making them unsuitable for residential and commercial use.● Depending on the material used in production, panels can have a blue or black hue.

Amorphous Silicon Panels

Amorphous silicon panels are another type that is widely used in India. The majority of houses’ outdoor lighting is powered by these tiny silicon panels. Amorphous modules are created using a thin, flexible material.

Features

● Amorphous silicon panels are inexpensive and constructed of non-crystalline silicon.

● They are 7% efficient and have a thickness of 1 micrometer.

● Amorphous silicon solar panels function similarly to monocrystalline and polycrystalline solar cells. The protons of the amorphous solar cell take energy from the sun’s rays. They then transfer it to the electrons, who then transform it into electric current to power various electrical devices.

Which Solar Panel Should I Choose?

Even though Mono-PERC solar panels may be the most cutting-edge and efficient technology now available, there are a number of other factors you should look into.

Monocrystalline or Mono-PERC panels offer the best power output and efficiency. This makes them ideal for installing a larger solar plant in a more condensed space. For instance, you may want to use your solar plant to the most extent possible if your electricity bill is quite expensive.

If you only have a small amount of installation space available, using monocrystalline panels will enable you to build solar plants with greater capacity in the same space. Although monocrystalline panels cost more upfront, having a larger plant will pay off in the long term by lowering your power costs far more than polycrystalline panels can.

Polycrystalline panels can be used since they are less expensive, particularly when there is enough rooftop space available. Moreover, these panels are presently an ideal choice if you plan on taking advantage of government subsidies.

Additionally, you need to keep in mind that only solar panels made in India are eligible for household solar subsidies. As a monocrystalline cell manufacturing industry in India is not available, only providing polycrystalline cells for projects is available. These solar cells are generally installed with the help of government funding.

Thin-film solar panels have a shorter lifespan and are normally not used for installations in homes or any other domestic setting. They typically have a higher use rate in bigger utility-scale power facilities. Also, we recommend that you avoid installing amorphous silicon panels in your home since they are not very energy-efficient.

Read More: Solar Panel Installation Guide

Conclusion

It may seem difficult to choose the best type of solar panels for your house. However, once you have all the facts, it becomes simpler to decide.

Before making a decision, it is advisable to consult with solar installation professionals who can assess your specific needs and provide guidance on the best type of solar panels for your home. With the right choice, you can harness the power of the sun and make huge savings on energy costs, all while contributing to a more sustainable future.

0 Comments